Hello, welcome to Hefei Vigon Material Technology Co.,Ltd. !

Hotline:15805691910

Application of graphene powder industrialisation

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-02-18

- Views:818

(Summary description)Graphene is the hardest and thinnest existing material known to exist in nature, with high light transmission, dense - no other material can penetrate except for protons, in addition to extremely high electron mobility, heat transfer rate and high current carrying capacity. It combines various excellent material properties and has a wide range of applications in new energy, electronic information, functional materials, new coating products, biomedicine, aerospace high precision machinery, energy saving and environmental protection. Therefore, graphene is not only considered as a strategic emerging material in the 21st century, but also as a landmark new material in the era of a new civilisation after stone, bronze, steel and silicon.

Application of graphene powder industrialisation

(Summary description)Graphene is the hardest and thinnest existing material known to exist in nature, with high light transmission, dense - no other material can penetrate except for protons, in addition to extremely high electron mobility, heat transfer rate and high current carrying capacity. It combines various excellent material properties and has a wide range of applications in new energy, electronic information, functional materials, new coating products, biomedicine, aerospace high precision machinery, energy saving and environmental protection. Therefore, graphene is not only considered as a strategic emerging material in the 21st century, but also as a landmark new material in the era of a new civilisation after stone, bronze, steel and silicon.

- Categories:Industry News

- Author:

- Origin:

- Time of issue:2023-02-18

- Views:818

Graphene is the hardest and thinnest existing material known to exist in nature, with high light transmission, dense - no other material can penetrate except for protons, in addition to extremely high electron mobility, heat transfer rate and high current carrying capacity. It combines various excellent material properties and has a wide range of applications in new energy, electronic information, functional materials, new coating products, biomedicine, aerospace high precision machinery, energy saving and environmental protection. Therefore, graphene is not only considered as a strategic emerging material in the 21st century, but also as a landmark new material in the era of a new civilisation after stone, bronze, steel and silicon.

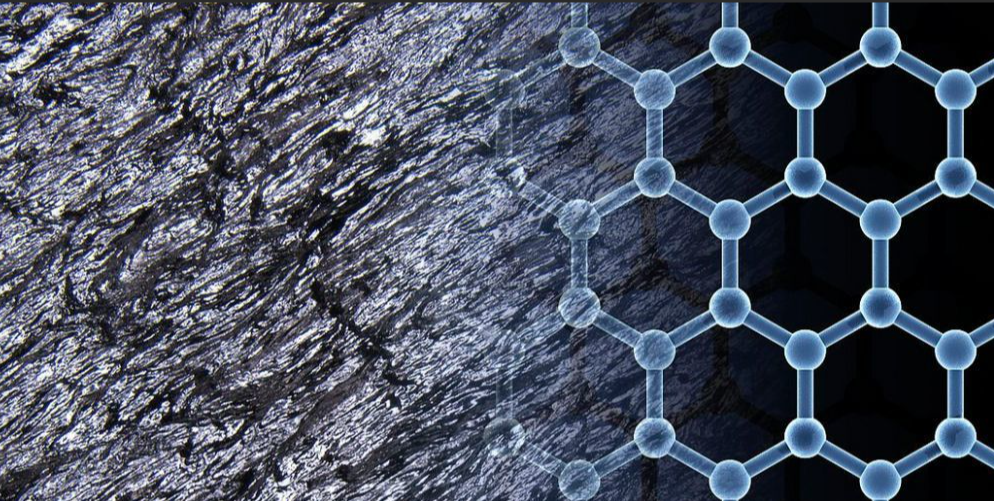

For the time being, graphene products are generally divided into two forms: graphene powder and graphene film. Graphene powder is currently mainly used in new energy, anti-corrosion coatings, composite materials, biosensors and other fields, with a wide range of applications, this paper focuses on graphene powder; graphene film is mainly used in flexible displays and sensors and other fields, with a relatively small range of applications. Graphene atomic structure graphene film corroded metal well-protected steel structure.

Graphene atomic structure

Graphene is used in traditional lithium batteries. Many of the raw materials for lithium batteries and graphene are nanomaterials, such as positive and negative raw materials are in the form of powder, the production process needs to be beaten into a slurry, the slurry will be coated to the positive and negative electrodes up. Carbon nanomaterials are already a mature battery conductive agent, and without changing the original process configuration, graphene can be used to replace the original conductive agent to improve the performance of the battery.

Graphene films

Graphene application in coatings. Graphene application in coatings mainly uses graphene's high conductivity, low resistance, high strength and anti-corrosion properties, etc. The products prepared are graphene conductive/heat generating/electromagnetic shielding coatings and graphene anti-corrosion coatings.

Graphene conductive/heat generating/electromagnetic shielding coatings. Graphene is by far the highest thermal conductivity material with excellent heat conduction properties; as well as two-dimensional surface electron conduction based on the simultaneous realization of the network chain, tunneling and magnetic differential efficient electron movement patterns, due to the friction and collision of electron movement to generate heat, infrared and surface radiation to achieve heat conduction, the electrical and thermal conversion rate of more than 99%. The graphene conductive/heat generating/electromagnetic shielding coating made by Microcrystalline Technology using these properties is safe, reliable, energy efficient, fast heating up, uniform heat generation, good weather resistance, good performance and flexible application.

Metal corrosion

Graphene anti-corrosion coatings. Graphene has a variety of properties: sheet barrier effect, the stacking effect of graphene's sheet structure, the formation of a "labyrinth" shielding structure in the coating structure, can effectively inhibit the infiltration, penetration and diffusion of corrosive media, to improve the physical barrier properties of anti-corrosion coatings; "conductive bridge "mechanism, the majority of the current traditional anti-corrosion coatings, zinc powder as the active ingredient. However, as the corrosion time lengthens, the zinc in the coating is oxidised resulting in a decrease in electrical conductivity, it is possible to block the electron transfer path and lose the role of cathodic protection, leaving the coating without anti-corrosion properties. If the graphene powder from Microcrystalline Technology is added to the anti-corrosion coating, the graphene structure makes the coating have good electrical conductivity, forming a stable long-term more stable electrochemical protection; the "hydrophobicity" of graphene and the high strength of graphene can enhance the stability of the anti-corrosion coating.

Graphene anti-corrosion coatings prepared using the above graphene characteristics, has a variety of advantages: graphene anti-corrosion coatings film strength, high adhesion, all aspects of physical and mechanical properties, excellent anti-corrosion performance, salt spray resistance significantly more than the general zinc powder anti-corrosion coatings 2000 hours, up to 5000-6000 hours; low specific gravity is not easy to sink, easy to build; paint film curing surface dense and stable, graphene hydrophobic, can be quite isolated from the substrate and moisture, air, etc.; anti-corrosion coatings only need to be cured at room temperature, or low temperature curing, reducing the cost of construction processes.

Scan the QR code to read on your phone

Recommended News

2022-04-19

2022-04-19

General Secretary Xi Jinping inspected the scientific and technological innovation product exhibition and visited the company's booth in person

2024-04-03

2024-04-03

Vigon Technology Invited to Appear at the 2024 International Conference on Display Technology (ICDT)

2024-03-30

2024-03-30

Happy reunion with Pengxiang,The Elites of Vigon Gathering from everywhere——Vigon Technology 2024 Spring Team building

2024-03-08

2024-03-08

Celebrate the 3-8 Women's Day with flowers and deepen Vigon company's party building activities

Follow us on social media

Copyright:Hefei Vigon Material Technology Co.,Ltd.

Contact Us

E-mail:sale@hfweijing.com

Website:http://www.hfweijing.com/

Add:Building C3, Science and Technology Industrial Park, No. 168 Xiangzhang Avenue, Hefei City

What services does Vigon provide you?

15805691910

15805691910

Inquery

Inquery